- Broomwade Compressor Service Manual

- Broomwade Compressor Manual Pdf

- Broomwade 6000e Manual

- Broomwade 6000 Manual

BroomWade filters are composed of specific filter elements, with features including high-grade filtration efficiency and temperature resistance. BroomWade Air Filters are designed so that they allow the volume of air to flow freely into the machine whilst giving maximum protection against dust particles. BroomWade stationary rotary screw compressors - both fixed and variable speeds - are the ultimate solution for the industry needs of small to medium sized companies. The whole range is designed for continuous use under even the most severe conditions, paying particular attention to modularity, energy consumption, low operating and maintenance.

Operation, Maintenance and Parts Manual for the BroomWade AC5 & AC7 Compressors and ACV5 & ACV7 Vacuum Pumps.

Broomwade C3938B Automatic Air Governor. Operating and Maintenance Manual with Parts Manual as Exploded Component Drawings.Filed with this document was an instruction sheet and parts drawings for Kismet Air Motors and Kismet KGS Hose Reels and these are included as well.

Broomwade TS1, TS1A and TS1B Compressors (Double-acting Stationary). Operating and Maintenance Manual with Parts Manual as Exploded Component Drawings.

Broomwade Compressors V65A Operating, Maintenance and Illustrated Spares Manual

BROOMWADE Rotair 75 (RA75) COMPRESSOR Operator's Instruction and Basic Service Manual.

Broomwade Compressor Service Manual

Broomwade Rotair 75 (RA75) Compressor Operator's Instruction and Basic Service Manual.

Broomwade Rotair 75 (RA75) Compressor Parts as Exploded Component Drawings with an electrical schematic.

Broomwade Compressors V100A Operating, Maintenance and Illustrated Spares Manual

Broomwade Compressors V200A Operating, Maintenance and Illustrated Spares Manual

Broomwade C3938B Automatic Air Governor. Operating and Maintenance Manual with Parts Manual as Exploded Component Drawings.Filed with this document was an instruction sheet and parts drawings for Kismet Air Motors and Kismet KGS Hose Reels and these are included as well.

Broomwade TS1, TS1A and TS1B Compressors (Double-acting Stationary). Operating and Maintenance Manual with Parts Manual as Exploded Component Drawings.

Broomwade Compressors V65A Operating, Maintenance and Illustrated Spares Manual

BROOMWADE Rotair 75 (RA75) COMPRESSOR Operator's Instruction and Basic Service Manual.

Broomwade Compressor Service Manual

Broomwade Rotair 75 (RA75) Compressor Operator's Instruction and Basic Service Manual.

Broomwade Rotair 75 (RA75) Compressor Parts as Exploded Component Drawings with an electrical schematic.

Broomwade Compressors V100A Operating, Maintenance and Illustrated Spares Manual

Broomwade Compressors V200A Operating, Maintenance and Illustrated Spares Manual

Broomwade Compressors V300A Operating and Maintenance Manual with Parts Manual as Exploded Component Drawings.

Broomwade Compressors V350, V500, VHP350 and VHP500 Operating and Maintenance Manual with Parts Manual as Exploded Component Drawings.

Broomwade Compressors VM500, VMH500, VM750 and VMH705 Operating and Maintenance Manual with Parts Manual as Exploded Component Drawings.

Broomwade Compressor Manual Pdf

Broomwade HPS Speed Riveters. Operation of prime pumps.

Broomwade Power-Vane Portable Rotary Compressors (made by Consolidated Pneumatic) - all models. Instruction and Maintenance Manual.

Broomwade (Compair Broomwade) Refrigerant Driers CD10-400, CBD90 and CBD120 Operator's Hand book.

Broomwade 6000e Manual

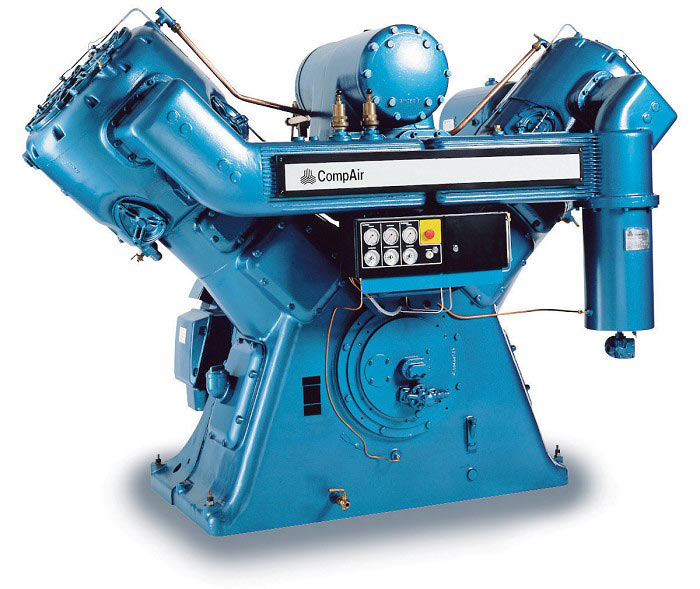

BROOMWADE (CompAir Broomwade) VMD1000, VMD1500 & VMHD100 Compressors.Operating, Maintenance and Parts Manual.

BROOMWADE (CompAir Broomwade) AC26, AC32, AC41 (N5) and N4 Compressors Brief Operating Instructions with Parts as Sectional Drawings.

CompAir BroomWade Cyclon 330: Transcript

Broomwade 6000 Manual

CompAir BroomWade Limited page 46 ..

page 17 Cyclon Series User Manual – General Description 6.3 Modulating Control (Optional) In the ‘Modulating' mode the opening and closing of the suction regulator inlet valve is controlled by the negative regulator. As the demand for compressed air rises and falls, the valve modulates between fully open and fully closed. When the compressor is starte ..

Page: 17CompAir BroomWade Limited page 4 WARRANTY The conditions of the CompAir BroomWade Warranty are set out in the company's standard Conditions of Sale available from the Distributor supplying the machine. MAINTENANCE To ensure the continued trouble-free operation of the compressor unit it is important that periodic maintenance and servicing are carried out in ..

page 11 Cyclon Series User Manual GENERAL DESCRIPTION Page Compressor 12 Air-End 12 Electronic Controller 12 Protection and Safety Equipment 12 Relief Valve 12 Blowdown System 12 Minimum Pressure Non-return Valve 12 Air/Oil System 14 Description 14 Operation 14 Regulation System 16 Description 16 On/Off Control 16 Modulating Control (Optional) 17 2 ..

Page: 11CompAir BroomWade Limited page 54 3.4.3 To Change the Oil Filter: The compressor must be stopped. 1. Open the door to the service area. 2. Unscrew the old oil filter from the manifold block and discard. 3. Apply a light film of oil to the seal of the new element and prime the new filter with oil. 4. To fit the new element, screw it into the manifold block u ..

CompAir BroomWade Limited page 56 3.5.1 Adjustment After Fitting New Drive Belt(s): 1. Release the 1 /4 turn fasteners and remove the LH side panel. 2. Loosen the lock nut (1) and turn the nut (2) clockwise until the adjuster (3) contacts the cut-out in the spring retainer (4). 3. Screw the nut (2) back one turn and tighten the lock nut (1). 4. Check that t ..

Page: 56CompAir BroomWade Limited page 40 2. PROGRAM MODE 2.1 Program Mode Routine ‘Program mode' is used to access, view and/or alter the operating parameters and options stored in the memory of the controller. 1. To enter the ‘Program mode' press STOP (B3) then press and hold PLUS (B4) and MINUS (B5) together. 2. After five seconds indicators L1 to L8 ..

CompAir BroomWade Limited page 50 2.1 Separator Filter Part Number Table Model Qty. Max Rated Separator Cyclon Pressure Filter (Bar) 330/337 1 7·5 to 13 98262-223 345 2 7·5 to 13 98262-223 2.3 Drive Belt Part Number Table (50 Hz) Model Qty. Maximum Rated Pressure 7.5 bar 8.2 bar 10 bar 13 bar 330 4 98080-152 98080-152 98080-152 98080-153 337 4 98080-153 98 ..

Page: 50page 25 Cyclon Series User Manual 5 COMMISSIONING Page Commissioning Procedure 26 Preliminary Checks 26 Pressure Calibration 27 Checking/Altering Program Mode Values 28 Final Checks 30 Negative Regulator (Modulating Control Only) 33 Commissioning Checklist 34 ..

page 27 Cyclon Series User Manual – CommissioningCyclon Series User Manual – Commissioning 1.2 Pressure Calibration Note: The values shown throughout these procedures are examples only. Ensure set values are compatible with the compressor model. No. Action Reason Display 1. Switch power ‘ON' at the isolator 0.0 Bar and allow the controller to initial ..

Page: 27page 51 Cyclon Series User Manual – Maintenance 1. Intake Air Filter 2. Suction Regulator 3. Oil Cooler 4. Drive Belt 5. Motor Bearings 6. Minimum Pressure/Non-return Valve 7. Separator Element 8. Oil Filter Element 9. Oil Drain Valve 10. Control Air Isolating Valve 11. Oil Filler Cap 12. Oil Level Sightglass 13. Air Cooler 14. Display Panel 15. Belt Tensi ..

page 7 Cyclon Series User Manual – Safety Procedures 3. GENERAL SAFETY PRECAUTIONS If using compressed air for cleaning purposes, ensure safety regulations are complied with and appropriate clothing and eye protection is worn. Never direct compressed air onto your skin or at other people. Never use compressed air to clean loose dirt from clothing. Before ..

Page: 7CompAir BroomWade Limited page 62 Q101 MCB R201 Temperature Sensor S101 Emergency Stop Button S201 Air Filter T101 Control Transformer Y101 Load Solenoid Y102 Drain Solenoid Option ELECTRICAL CONNECTIONS DIAGRAM F1 Fused Terminal 1·6A F2 Fused Terminal 3·15A F101 Motor Overload Relay KM101 Main Contactor KM102 Star Contactor KM103 Delta Contactor M101 Dri ..

CompAir BroomWade Limited page 12 GENERAL DESCRIPTION 1. COMPRESSOR The unit is a fully enclosed, air cooled, single- stage, rotary screw compressor. The compressor air-end is belt driven by an electric squirrel-cage induction motor. The drive belts are mounted on pulleys fitted to the shafts of the drive motor and air-end. The compressor unit consists of th ..

Page: 12CompAir BroomWade Limited page 6 2. WARNINGS, CAUTIONS AND NOTES 2.1 Warnings Warnings call attention to operations or procedures involving specific hazards which could cause injury or death and are identified by the following symbols on the unit and in the text of the manual. Il 2 sturmovik battle of stalingrad tpb. WARNING: RISK OF DANGER WARNING: RISK OF ELECTRIC SHOCK WARNING: RISK OF HOT SURF ..

page 45 Cyclon Series User Manual – Operation 4.4 Remote Group Fault Output 4.4.1 Group Fault Relay The control card is fitted with a group fault relay, the relay contacts being available for switching remote facilities. The relay contacts are rated for a maximum of 250V ac at 5A and are connected to controller terminal X08, pins 9 and 10. 4.4.2 Group Faul ..

Page: 45page 19 Cyclon Series User Manual LEADING PARTICULARS 3 ..

page 61 Cyclon Series User Manual APPENDIX 1 Electrical Connections ..

Page: 61